The problem faced by the manufacturing industry globally today is the universality of high cost and the lack of precision. Many companies are still relying on the conventional machining process, which results in inefficiency and serious precision-related risks to the final product quality. The problem essentially lies with the suboptimal CNC Machining techniques, in which the wrong choice in material and the lack of transparent processes mean that the conventional techniques fail to address the conflict between high cost and high precision effectively.

This paper proposes to present the techniques of high efficiency in precision machining in the areas of cost and precision..

What is Precision CNC Machining and Its Importance in Manufacturing?

Precision CNC Machining is a subtractive manufacturing technique in which the actions of factory machinery are programmed using predetermined computer software. This manufacturing technique is the very basis of modern manufacturing and is a forerunner of the aerospace industry, the healthcare industry, and the automotive industry. According to ASMEspecifications, the accuracy of precision CNC machining is the capability of maintaining a tolerance of ±0.005mm, which is unachievable through traditional machining processes.

Its significance is doubly important. Firstly, this technology is highly effective when it comes to precision and efficiency. This is because digital control enables the CNC machine to carry out complex programming repeatedly and correctly, having minimal chances of any error being introduced by humans. This technology increases the efficiency of the Business of Manufacturing. This means small-batch and customized manufacturing is possible. This automatically calls for cost-optimization techniques to be utilized in manufacturing.

How to Reduce Manufacturing Costs through CNC Machining Optimization?

Cost control in CNC machining cost is one of the main concerns of any manufacturing enterprise. Any good CNC machining quote should clearly explain all major factors involved in the pricing.

Analysis of Cost Drivers

The main factors affecting total cost of manufacturing are material waste, machining time, tool life, and subsequent processing. For example, inefficient cutting data may lead to faster deterioration of the tool, thus raising the total CNC machining cost unintentionally.

Cost-Saving Techniques

These include Design for Manufacturability (DFM), and batch optimization. Working closely with manufacturers on avoiding features of parts that include deep cavities or sharp interior angles, or by combining order fulfillment so that setup costs can be distributed over higher volumes of parts per order, can be very cost-effective.

Quality Management and Standard Certification

Following international standards, for example, from ISO, shows the manufacturer’s compliance with quality and efficiency, which is a direct factor in the accuracy of quotes..

- The Role of ISO 9001 Certification

Achieving ISO 9001 certification means that the company had implemented an effective quality management system within their manufacturing business. The quality management system helps in streamlining waste, quality, and creates a reliable foundation for an accurate CNC machining quote.

- Strategic Sourcing with Certified Partners

There is the advantage of quality as the service is combined with cost-effectiveness through the use of a partner company that is ISO-certified in CNC machining service china. This is because the company is likely to have a mature infrastructure which ensures cost management.

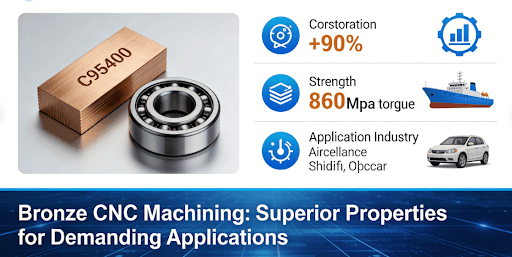

What are the Unique Advantages and Applications of Bronze CNC Machining?

CNC Machining Bronze: This process takes advantage of the unique strengths offered by the ancient alloy, bronze, which has remarkable strength, fantastic corrosion resistance, and outstanding wear resistance. Relative to brass CNC machining, the material bronze (such as C95400 aluminum bronze) has much greater tensile strength than brass and outperforms the alloy in environments with high corrosion, such as those encountered in saltwater.

Notwithstanding, bronze processing requires distinct conditions and tools for optimal processing. In the domain of large CNC machining, for instance, the production of propellers with a diameter of several meters, issues like thermal expansion and vibration play a prominent role. This is countered by the usage of modern five-axis CNC machines as well as observation systems for precise processing. The meticulous discussion about this can be read about in this technical manual:CNC Machining Bronze.

What Key Factors to Consider When Choosing a Custom Parts Manufacturer?

It is essential to identify the right custom bronze parts manufacturer to ensure the project’s success. Other than the cost at the start, there are various considerations that should be carefully thought through.

Technical Capability & Certifications

The company needs to have the requisite hardware or equipment in this regard, including multi-axis CNC machines. AS9100D certification, for instance, is quite demanding in this respect, especially where aircraft production is concerned. A company like JS Precision sets a very good example in this regard, taking into account quality and technical abilities.

Supply Chain Model & Collaborative Model

Typical benefits that come with the use of the CNC machining service china include its supply chain and collaboration system.

- Efficiency of Supply Chains

The mature industrial environment that China has established provides a competitive advantage on pricing for raw materials like high-quality bronze billets that would be 20-30% cheaper than those obtained in a Western setting.

- Collaborative Experience:

Professional manufacturers in China have the capacity for project management and communication, with the ability to deliver valuable analysis for DFM, ensuring that the design process remains cost-effective from the start. Reports from the Society of Manufacturing Engineers (SME)emphasize the increased use of Chinese services, citing cost-effectiveness and technical skill. To learn more about Chinese services, click through to this source:CNC machining services.

How to Ensure Precision and Efficiency in Large-Scale CNC Machining?

Large CNC machining involves more than just enlarging a small component. However, the primary challenge is to integrate “large scale” with “precision.” This is achieved through current engineering practices.

A sound basis for accuracy and efficiency is provided by three areas. Multi-axis Machining Technology enables the production of complex geometries in one setting. This helps to eliminate the problem of accumulation of errors. Real-time Monitoring and Compensation involves the use of process probes to eliminate deviations, which are due to the effects of tool wear and/or the effects of temperature. Strict Process Control includes the accurate control of each process step, from the process of relieving stresses after roughing to the parameter optimization process after finishing.

Precision Engineering standards issued by ASME bring home the fact that, when the design incorporates stiff machine structures and superior control, there is absolutely no reason why highly precise work can’t be accomplished even when parts are very large. This definitely raises the Business of Manufacturing.

Conclusion

In summary, precision CNC machining, achieved through the effective selection of materials and supply chain cooperation, can lower manufacturing prices and advance product quality.

For those experiencing manufacturing dilemmas, it would be best to consider professional help right away in order to get a tailored CNC machining solution and maximize the entire manufacturing process.

Author Bio

This article was written by an industry expert with extensive experience in precision engineering, focusing on innovation in CNC machining and holistic cost-optimization strategies.

FAQs

Q: What is the typical accuracy range for CNC machining?

A: Accuracy for the common CNC machining is usually ±0.005mm, depending on material and machine. It can be improved by optimizing parameters, while ISO standards make sure that reliability is appropriate.

Q: How to get an accurate CNC machining quote?

A: Please provide detailed design files and requirements. The quote issued by a manufacturer would be transparent, based on material, quantity, and complexity. Early communication prevents hidden costs.

Q: Which industries is Bronze CNC machining good for?

A: Bronze CNC machining is ideal for aerospace, marine, and automotive industries due to its excellent corrosion resistance, high strength, and wear properties. Selecting the correct bronze alloy is crucial for optimal performance

Q: What are the main difficulties with large CNC machining?

A: Thermal deformation and tool wear are challenges that can be somewhat mitigated by in-process measurement and robust quality controls. Certifications such as IATF 16949 help manage

Q: What are the benefits of Chinese CNC machining services?

A: The advantages are lower costs, efficient supply chains, and internationally competitive technology. A certified supplier like JS Precision means quality assurance.