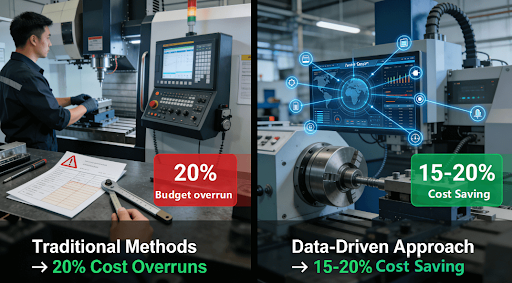

The current industrial manufacturing sector has a very dismal state of affairs when it comes to the production of gears, which boils down to the fact that the product needs to align with economy as well as industry standards. The current production techniques, which are very dependent on human expertise, come with the possibility of unexpected results, which can be in the range of more than 20% percent of the overall budget.

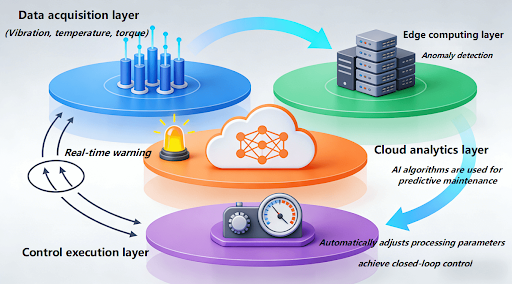

In this article, the transformative technology being presented is data-driven gear machining services. This technology uses real-time sensors, AI analytics, and closed-loop controls to optimize the entire process involved in manufacturing gears. We will discuss in this article how this technology transforms the manufacturing of gears.

What Is Data-Driven Gear Machining and How Does This Approach Compare to Traditional Machining?

Data-driven gear machining services marks a paradigm shift in manufacturing, moving from a reactionary and experience-driven approach to a proactive and data-driven paradigm. The process requires the constant flow and analysis of data throughout the entire gear machining process to facilitate proactive adjustments for optimal results.

Core Components Definition

Fundamentally, data-driven gear machining spans the incorporation of several core technologies. Sensors made IoT-capable are connected to machine tools to provide real-time feed on cutting forces, spindle vibration, motor torque, and temperature. Such data flows to edge computers, which are then connected to cloud-based analysis software where machine learning models pick out patterns, predict the wear of cutting tools, and point out discrepancies before the defect occurs. Contrast this approach to conventional machining, where the criteria for decision-making are set based on scheduled maintenance or post-machine analysis, leading to lagged response times to errors created.

Contrasting with Traditional, Experience-Driven Approaches

The conventional gear machining indexing is based on certain defined variables and is very machinist skill-dependent. For example, tool changeovers may be indicated by time or by when parts exceed quality control requirements. These cause two fundamental inefficiencies: tools may be changed too soon, thereby shortchanging their useful life, or tools may be run past their ideal usage point, which can create issues regarding surface finish and dimensions. The analytical model leverages precision gear machining analytics that precisely define when tools need to be changed, thereby fully optimizing resource usage and quality factors. Following guidelines like ASME Y14.5-2018, which strongly urges clear geometric dimensioning & tolerancing (GD&T), this digital thread offers unerring ability and totally dispenses with any subjective interpretation.

The Role of Interoperability and Data Synthesis

An efficient system is not limited to just machine data. Instead, it integrates and synthesizes data from multiple sources, such as CAD/CAM models, tool presetter logs, and Coordinate Measuring Machine (CMM) results. This process yields a comprehensive digital twin of the manufacturing process. By comparing sensor data from the shop floor with the expected output from the digital model, the system can perform adjustments for deviations automatically. If the system detected that thermal expansion was occurring, for instance, the machine could issue real-time tool path adjustments to stay within tolerance-a degree of control that is out of reach when using traditional methods. Hence, a data-driven gear machining service represents the most feasible option for the execution of such a cohesive method.

How Can Real-Time Monitoring Contribute to Gear Consistency and Performance?

Realtime monitoring is the nervous system of data-manufacturing. Without it, quality control is a final step in manufacturing; real-time monitoring converts the final step into a phase of the manufacturing process.

- The Mechanics of In-Process Monitoring: Modern systems of process monitoring have acoustic sensors for emissions and vibroanalyzers installed directly on the machining center. They can detect even the slightest changes in the acoustic and vibrosignatures associated with the process of cutting, pointing to the development, for instance, of micro-chipping in the cutting tool or the appearance of chatter. The system enables immediate remedial measures, which in many cases can be done by the machining center’s control system automatically. This proactive strategy eliminates the production of defect goods, ensuring that all the gears produced have the necessary surface integrity and geometric accuracy. This control strategy is one of the cornerstones of the effective Quality Management System, as postulated in ISO 9001:2015.

- Quantifying Performance Gains with Statistical Process Control (SPC): The advantage of this constant stream of data is enabled by Statistical Process Control (SPC). The critical performance factors of Cpk (Process Capability Index) calculations are carried out in real-time environments. A conventional production process may have a Cpk of 1.0, meaning it is only just meeting specification requirements. The optimized gears performance by use of data-driven decision-making processes have shown cases where the Cpk ratios exceed 1.67, meaning it is highly capable and reliable with low variation on the manufacturing process.

- Case in Point: Eliminating Heat Treatment Distortion: One of the common issues in gear production is that the gear might distort during heat treatment. The data-driven method, in this case, is useful in understanding how machining parameters would influence gear dimensions after heat treatment. With time, AI would be able to forecast the behavior of gear dimensions during machining. It would, in turn, provide advice on the best machining parameters that would be needed to negate the distortion, ensuring that the final gear meets the required dimensions without incurring extra costs.

Cost-Control Strategies Enabled Through Data-Driven Machining Analysis

Apart from quality, cost saving is one of the most important factors that ensure the adoption of data-driven practices. Data analysis of the complete lifecycle of manufacturing can help eliminate wastage to a great extent.

Tool Life Optimization and Consumables Cost Reduction

Tooling is one of the most significant recurring expenditures. Instead of using conservative, life-fixed estimates, data-driven analysis uses tool wear simulation that factors real cutting conditions. This enables it to predict the wear life of each cutting tool accurately to a level of over 95% accuracy. This makes it possible to replace a tool exactly when it is needed, eliminating early tool disposal that results in scrap due to an undesirable down time resulting from a worn-out tool. It makes cost-effective gear machining feasible by reducing tooling expenditures by as much as 15-20%.

Minimizing Scrap and Energy Consumption

This means that, through real-time anomaly detection, it would realize the exact moment a part starts getting machined wrong and thus could stop right there and then, rather than wasting precious material and time on the machine. Furthermore, analytics can optimize production scheduling and machine utilization even more, decreasing idle times. Through the analysis of energy consumption patterns, the system also identifies measures for running equipment at peak energy efficiency, with contributions toward low operational overhead and furthering cost-effective production goals.

Influence on Overall Equipment Effectiveness (OEE)

The best way to measure productivity in a manufacturing operation is Overall Equipment Effectiveness (OEE), the sum of availability, performance, and quality. Improved performance all begins with data, and the three areas that benefit directly from data-based improvements and advancements include availability through predictive maintenance, performance optimization via optimal feed rates, and real-time Software Control Program (SCP) or Computer Numerical Control (CNC) machining that guarantees a high level of quality. Enhancing OEE from current levels, which stand at 60% in today’s traditional shops, to the best in the world, which stands at 85%, would, therefore, mean a drastically lower total unit cost.

In What Manner Does the Data-Driven Approach Enforce Compliance with the AGMA and ISO Gear Specifications?

In the regulative industry, compliance has to happen without question. Data-driven machining removes the administrative aspect of compliance, merging it automatically with the production process.

- Automated Validation against Digital Standard Libraries: The equipment comes with digital libraries consisting of international standards AGMA 2008 and ISO 1328. As the gear manufacturing or inspection process continues, it will immediately compare critical gear dimensions such as profile deviations, pitch error, and tooth alignment to the respective limits as per the international standard. However, instead of relying on the concept of statistical sampling or 5S inspection, 100% full inspection has been implemented via continuous inspection processes as soon as there is any variation, calling for immediate correction with no possible risk to product compliance.

- Traceability and Auditability of Unbreachable Data: Traceability represents an area of utmost importance to businesses that manufacture gears to be utilized in the aerospace, medical, or automotive industry. The data-based system creates an electronic pedigree automatically for every batch of gears. The pedigree contains all the information about the raw material certificate, processing, sensor data, and the final CMM inspection report. Information from an audit trail can be called up immediately, and it illustrates unwaivering support to the gear compliance regulations and also traces the quality control process. This requirement forms an important part of compliance with IATF 16949 and AS9100D certification.

- Consistency in Global Production Centers: For the mass production companies. If the companies have manufacturing facilities located in various sites, the data model will ensure that the quality is standardized without considering the location of the manufacturing facility. The best machining technique combined with the desired quality level is put into a digital form for use in all facilities. This will eliminate the problem of ‘tribal knowledge.’ This means that no matter the location of the gear production site; whether in Asia or North America, the quality is the same.

What Are the Key Steps to Implementing a Data-Driven Gear Machining System?

Converting to an operation running on data can be termed an integrated process, for which appropriate planning and execution are also needed. The step-by-step process, which has been defined in advanced SOPs, would facilitate executing an operation in this manner.

Phase One: Feasibility Study and Technology Gap Analysis

The journey begins with a comprehensive audit of the current state. This involves process mapping to identify all data sources and sinks, followed by a technology gap analysis to determine what new hardware-sensors and network infrastructure-and software-analytics platforms-are needed. A critical step is the definition of clear KPIs (target OEE, scrap reduction, throughput increase) by which the success of the project will be measured.

Phase Two: System Integration and Pilot Deployment

First implementation should not be a full-scale rollout; rather, it should be piloted on a selected production line or on some gear family. This phase will include the physical installation of sensors, network setup, and integration of the software platforms. Data scientists and process engineers collaborate to build and train initial AI models. The objective of the pilot will be to validate the technology, show clear ROI, and are supposed to build confidence among the workforce-a key step for how to optimize gear machining effectively.

Phase Three: Scaling, Training, and Nurturing the Data-Driven Culture

Following the success of the pilot implementation, the system can be replicated throughout the shop floor. Yet, technology is only part of the equation. A robust change management process is also essential. This encompasses training the operators, the quality inspectors, and the maintenance team in the interpretation of the insights provided through the system. Creating an organizational culture in which decisions, and not guesses, are made is imperative for success, which is in line with the ideology of Continuous Improvement of ISO 9001. This is akin to the “post-publication interaction” stage of managing the lifecycle of content.

How Have Manufacturers Achieved Success with Data-Driven Gear Machining?

Case studies prove the practical advantages of this method and are definitely the direction to follow when other companies contemplate the process.

Case Study: Improving the Reliability of Wind Turbine Gearboxes

In the case of a producer of large planetary gearboxes intended for use in wind turbines, the issue arose in the form of high warranty costs because of premature bearings and gear failures. The reason underlying this problem had been identified to be micro-geometric variation in the gear teeth that had not been detected by conventional inspection methods. In order to address this concern, the company integrated a data-driven approach with in-process grinding analysis and found that certain unique vibrations during grinding correlated with gear topography. The process was then set to adjust grinding based on the parameters that contributed to undesirable micro-geometry. The outcome included a test life improvement of 40% in gearboxes.

Agile Low-Volume Production of Specialized Vehicles

A supplier of specialized military and agricultural vehicles needed to manufacture small batches of high-strength custom gears profitably. Traditional methods included time-consuming setup processes that often resulted in mistakes. By embracing a data-driven approach, they built a digital library of proven machining strategies for various gear geometries. Given a new order, the system was able to suggest optimal parameters with speed, drastically reducing setup time and first-part qualification. This agility enabled them to compete in the high-mix, low-volume market, transforming what had been a cost center into a competitive advantage and the heart of industrial innovation.

Conclusion

The fact is, data-driven gear machining services have become a requirement, no longer a privilege, in a competitive market. Using the technology that integrates data, predictive models, and control systems, companies can unlock a new dimension in the performance of their gears, massive reductions in expenses, and guaranteed compliance. This approach is the future of smart and intelligent manufacturing, which has the capability to convert a difficult, critical, and complex task like the production of gears into a precise, efficient, and optimized process.

FAQs

Q: What type of information is required for effective data-driven gear machining?

A: The most important data involves real-time values from sensors (such as cutting forces and vibration spectra), tool life, machine condition data, and post-process data from CMMs. This data, when combined, enables the use of predictive analytics.

Q: How does the data-driven machining cut costs relative to the traditional machining process?

A: This is achieved through a number of mechanisms: maximization of tool life, reduction of error rates of conversion considerably due to the ability to detect errors in real time, decrease in unplanned downtime through predictive maintenance, and optimization of energy use. The overall effect of this is a decrease in cost per good part.

Q: Can small manufacturers afford data-driven gear machining solutions?

A: Absolutely. The scalability of these IIoT platforms means that small to medium enterprises can start with one important machine. The ROI associated with minimizing the amount of scrap generated means that it typically pays back within less than 12 months.

Q: Data-driven compliance-and how does this relate to global guidelines like AGMA?

A: The system relies on digital templates of standards, such as the AGMA 2008 standard and the ISO 1328 standard. When data is gathered, it is automatically compared with the templates. The moment there is a lack of conformance, an alert goes off, and the system ensures spec is met by the part.

Q: What are the dangers of failing to incorporate data-driven methods when manufacturing gear components?

A: There would be a risk to the manufacturers from being left behind in the competitive race because of the added costs, variability in quality, and the growing demands for traceability from the original equipment manufacturers.

Author Bio

The expertise of the author includes working in the area of Precision Manufacturing at LS Manufacturing, and it helps engineers and researchers to overcome challenges in the manufacture of gears in the aerospace, energy, and automobile industries. They have expertise certifications such as IATF 16949 and AS9100D to provide solutions for high-quality work. For more information about them, visit the gear machining services page.